SEO for manufacturing companies is critical in today’s competitive tech landscape, where visibility drives business success. In this fast-moving world, electronic manufacturing services (EMS) play a vital role in turning ideas into tangible products. These services play a vital role in producing everything from smartphones to the smart home devices we use daily. But how exactly do they work, and why are they so important?

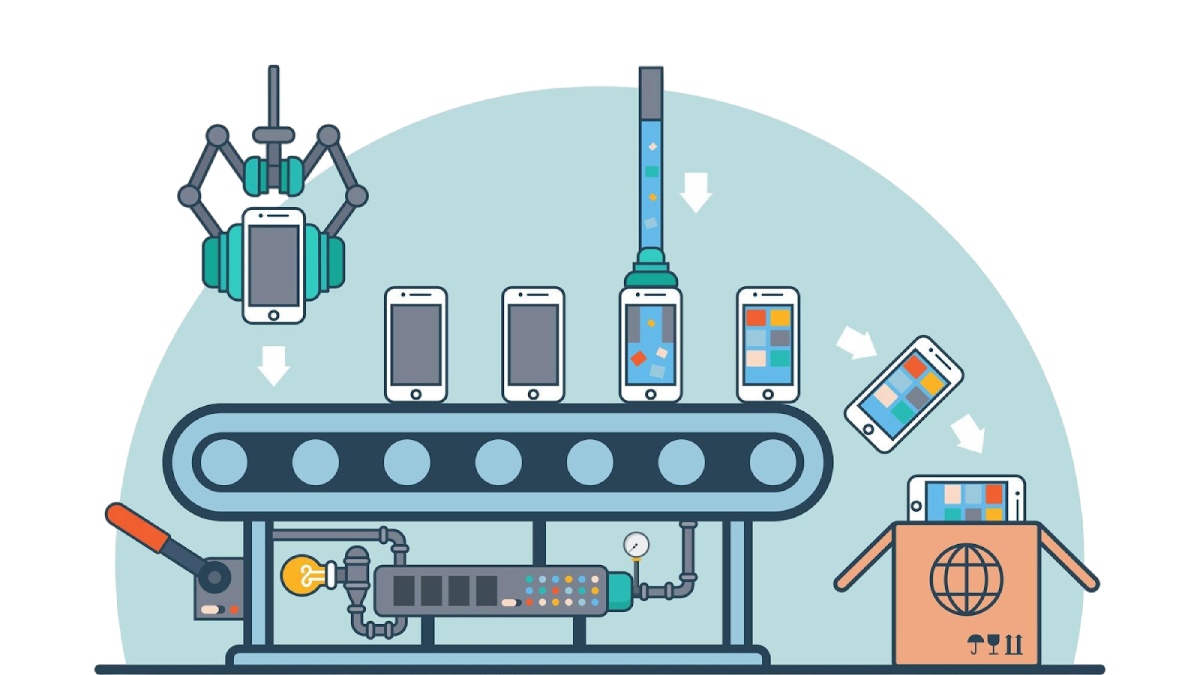

At its core, EMS electronic manufacturing involves designing, assembling, testing, and distributing electronic components or systems. Whether you’re an original equipment manufacturing (OEM) company launching the latest tech gadget or a startup with an innovative idea, EMS providers make the complex process of production manageable.

The electronic manufacturing services industry touches multiple fields, from semiconductor manufacturing to automotive and healthcare technologies. As technology continues to evolve, EMS services are becoming even more critical to helping businesses streamline their operations, reduce costs, and meet the increasing demand for cutting-edge devices. And of course, for anyone involved in it, EMS is a game-changer that keeps the industry running smoothly.

Let’s explore how EMS helps drive innovation, powers semiconductor manufacturing, and plays a crucial role in this industry.

What Exactly Are Electronic Manufacturing Services?

Simply put, EMS refers to companies that help other businesses produce electronic products. EMS providers are specialists in handling everything from the design and development stages to prototyping, testing, and mass production.

These services are especially valuable for OEM companies, as they allow OEMs to focus on what they do best—innovation and development—while leaving the heavy lifting of production to EMS experts.

One critical part of EMS is semiconductor manufacturing, which involves creating the tiny, complex circuits essential for most modern electronic devices. This industry plays a huge role in powering all the gadgets we use, from smartphones to electric cars and more. EMS providers often act as the crucial link between innovative designs and final products, ensuring that semiconductor manufacturing components are precisely integrated into tech products.

The Link Between Electronic Manufacturing Services (EMS) and Original Equipment Manufacturing

When companies innovate new tech products, they don’t always have the resources or expertise to handle production themselves. Enter EMS. For original equipment manufacturing companies, EMS provides a way to outsource the complicated task of manufacturing. This saves time, cuts costs, and ensures that the production process meets the highest standards.

EMS providers handle everything from sourcing materials and managing the supply chain to the assembly of products. This is especially valuable for companies in the semiconductor manufacturing industry, where precision and quality are critical.

Working with EMS providers means that original equipment manufacturing companies can maintain a lean operation without investing in the costly infrastructure needed for manufacturing. This partnership allows OEMs to scale up production quickly to meet market demands while staying competitive in the fast-moving world of tech.

The Semiconductor Manufacturing Industry: The Heart of EMS

At the core of many EMS processes is semiconductor manufacturing. Semiconductors are the essential building blocks of all electronic devices, from computers to smartphones and beyond. But manufacturing these tiny chips requires specialized technology and expertise, which is why EMS companies that specialize in this industry are so vital.

In this industry, EMS providers work with cutting-edge technologies to produce high-quality chips and components. These semiconductors are then integrated into larger systems like AI-powered devices, IoT gadgets, and 5G networks.

This collaboration between EMS and the semiconductor manufacturing industry is key to advancing technology. As demand grows for smaller, more efficient, and more powerful devices, EMS companies work hand-in-hand with semiconductor manufacturing to push the boundaries of what’s possible.

How EMS Drives Innovation

One of the biggest advantages of working with EMS providers is their ability to foster innovation. By taking on the heavy lifting of production, EMS allows OEM companies to focus on research, development, and strategy. This division of labor ensures that OEMs can stay at the forefront of technological advancements while leaving production challenges to the experts.

EMS companies are not just manufacturers; they’re partners in innovation. By working closely with this industry, EMS providers help OEMs integrate the latest technologies into their products. Whether it’s creating smaller, faster semiconductors for new gadgets or improving the efficiency of existing devices, EMS providers are critical in turning visionary ideas into reality.

With the rise of AI, 5G, and IoT, the EMS industry is driving some of the most exciting advancements in technology. From smart cities to autonomous vehicles, EMS is helping shape the future by enabling companies to bring groundbreaking products to market faster than ever before.

Why Companies Choose EMS Providers

The benefits of working with EMS providers are clear: scalability, expertise, and cost savings. EMS companies can ramp up production quickly, navigate complex supply chains, and ensure that every product meets strict quality standards.

EMS providers use advanced tools and technologies, including automated assembly lines, real-time quality monitoring, and cutting-edge testing procedures. This means that companies can trust that their products will be manufactured efficiently and to the highest possible standards.

Partnering with EMS providers also allows companies to be more flexible and responsive to market changes. As demand for new technology grows, companies need to be able to scale production quickly. By working with EMS, businesses can reduce overhead costs and the risks associated with investing in their own manufacturing infrastructure.

Future Trends in EMS

Like any industry, the EMS electronic manufacturing industry faces challenges—one of the biggest being the ongoing global chip shortage. This shortage has impacted everything from consumer electronics to automotive manufacturing, highlighting the critical role the semiconductor manufacturing industry plays in the global economy.

EMS providers are rising to this challenge by diversifying their supply chains, improving logistical operations, and adopting new technologies. Many the EMS electronic manufacturing industry companies are investing in AI, robotics, and machine learning to improve production efficiency and accuracy. These innovations not only help overcome current challenges but also pave the way for a more resilient and adaptable EMS industry in the future.

Looking ahead, the future of EMS is bright. As technology continues to evolve, EMS companies will play a critical role in shaping the next generation of tech products. Whether it’s helping to bring AI-powered devices to market or enabling the widespread adoption of 5G and IoT technologies, EMS is poised to lead the way in the tech revolution.

The Vital Role of EMS in Technology’s Future

The EMS electronic manufacturing industry is a key player in the future of technology. By providing essential services to OEM companies, EMS providers help bring innovative products to life. Their role in it ensures that technology continues to advance, pushing the boundaries of what’s possible.

As we look to the future, the EMS industry will continue to play a critical role in driving innovation, improving efficiency, and helping companies meet the growing demand for new technologies. Whether you’re a tech enthusiast, a business owner, or simply someone who loves gadgets, EMS is shaping the products of tomorrow and impacting the way we live, work, and play.

By working with EMS providers, companies can focus on innovation, knowing that the complex process of production is in expert hands. As the tech world continues to evolve, so too will the role of EMS in bringing the next generation of devices to life.

Recent Posts

- Top 10 Lead Generation Strategies That Work in 2025

- Top 10 Ways to Speed Up Your Website and Improve User Experience

- Top 10 Features to Look for in a Website Development Company

- SEO Company vs. Freelancer: Which is Best for Your Business?

- How a Digital Marketing Agency in India Can Boost Your Facebook Ad ROI